21 Feb PELLETS IN FEBRUARY: PRICES HAVE FALLEN SIGNIFICANTLY

PELLETS IN FEBRUARY: PRICES HAVE FALLEN SIGNIFICANTLY

PRESS RELEASE PROPELLETS AUSTRIA

20 February 2024

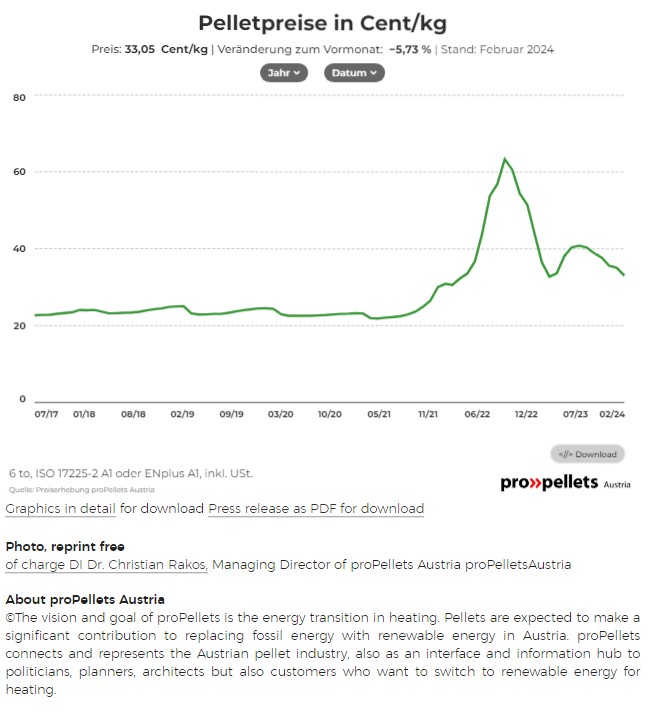

Prices for wood pellets fell in Austria for the sixth time in a row in February.

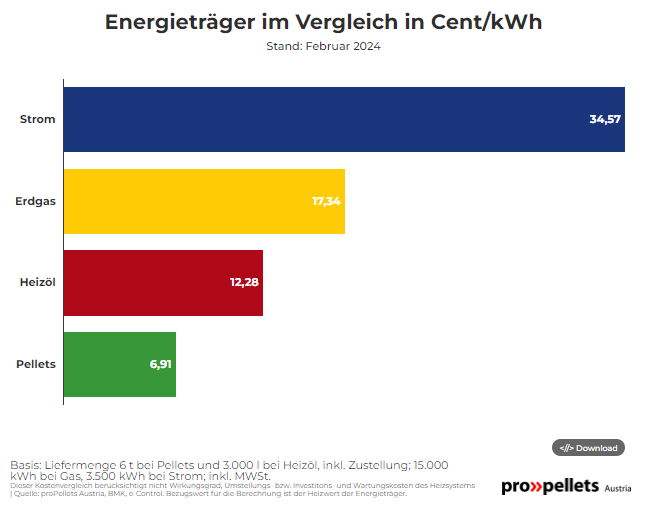

Pellets cost an average of 33.05 cents per kilogram, almost six percent less than last month. Compared to February of the previous year, this is almost 25 percent less.Natural gas and heating oil are much more expensive – natural gas costs 151 percent, heating oil 78 percent more. This is a continuation of a positive development for consumers. If you use pellets, you save a lot of money.

Heating with extra-light heating oil and natural gas is expensive

For a household that consumes 3000 litres of heating oil per year, the use of pellets would currently save around 1,547 euros per heating season.

Compared to a natural gas heating system, which consumes 30,000 kWh, pellets would enable savings of over 3,100 euros per heating season.

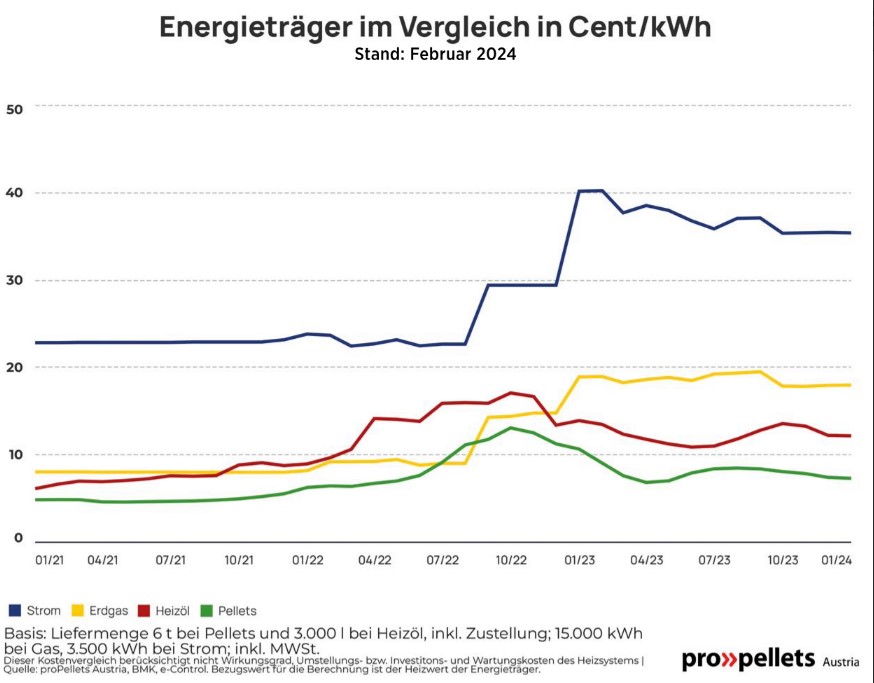

Long-term comparison shows: Pellets are significantly cheaper than oil and gas

Pellets have the edge in the long term. A comparison of the February 2021 and 2024 prices for electricity, extra-light heating oil, natural gas and pellets shows how crisis-proof heating with wood pellets is. Heating oil has become almost twice as expensive in the same period. Electricity now costs half as much. Natural gas has more than doubled. Pellet prices are subject to much lower fluctuations compared to fossil fuels over the long term.

Subsidies. Demand for pellet heating systems is increasing

With up to 18,000 euros, the new federal subsidy supports the switch from oil or gas heating to pellet heating. In addition, there are the state subsidies. For households with a low income, costs of up to 35,893 euros are covered. A two-person household with two children and a joint net income of a maximum of 3,998.40 euros would benefit from this maximum subsidy.

Christian Rakos, Managing Director of the Austrian Pellet Association, emphasizes: “There are now very high subsidies to move away from oil and gas heating systems. If you switch now, you save a lot of money and can rely on state-of-the-art heating technology and an energy storage system in the basement that smells of wood. Heating with oil and gas will hopefully soon be history. The demand for pellet heating systems is currently higher than ever before.”